Packaging in the pharmaceutical industry is more than a mere box or label: it plays a pivotal role in providing safe, effective medication to its intended recipient. Whether it’s a tablet blister pack, a plastic syringe, or a neatly folded carton holding multiple vials, pharmaceutical packaging ensures that medicines stay potent, uncontaminated, and properly identified.

Over the years, the types of pharmaceutical packaging have evolved alongside changes in medicine formulations, regulations, and technology. Today, packaging plays an essential role in both protection and communication, with a growing emphasis on safety, sustainability, and branding.

The Many Forms of Pharmaceutical Packaging

Pharmaceutical products are packaged in different formats depending on their form, dosage, handling needs, and market requirements. Some of the most common medicine packaging types include:

Blister packs: Often made using pharmaceutical plastic packaging and aluminum, blister packs are widely used for tablets and capsules. They’re ideal for protecting products from moisture and contamination while also offering clear visibility and patient convenience.

Bottles and vials: For liquid medicines, syrups, and injectable drugs, high-quality glass and plastic containers are used. The choice of medicine packaging material depends on the chemical stability of the drug.

Sachets and pouches: Typically used for powders, granules, or topical products, these formats are lightweight and efficient for single-use applications.

Cartons and boxes: Pharmaceutical packaging boxes and pharmaceutical carton packaging serve as outer layers that organize and protect primary packaging. These are often where most of the branding, dosage information, and compliance markings appear.

Ampoules and prefilled syringes: Sterile and ready-to-use, these forms are important in hospitals and clinics where precision and safety are paramount.

Behind every medicine you see on a shelf, there’s a thoughtful medicine packaging design that considers how the user will interact with it—and how to keep it secure.

Standards and Guidelines That Shape Packaging Design

The development of any pharmaceutical package must adhere to strict standards. Regulatory bodies such as the FDA (in the United States), EMA (in Europe), and other global health authorities enforce pharmaceutical packaging guidelines that cover everything from materials and labeling to traceability and tamper protection.

One of the most referenced standards globally is ISO 15378, which governs the quality management systems for medicine packaging materials that come into contact with the drug. These materials must not react with the contents, must preserve the drug’s properties, and should be free from contaminants.

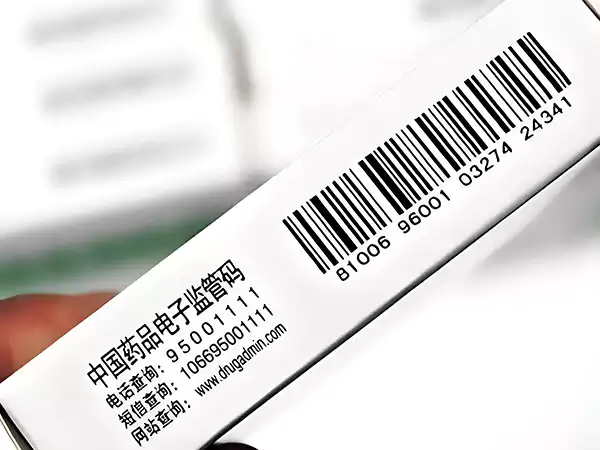

Additionally, pharmaceutical packaging design guidelines often dictate how labeling and dosage information should be presented. In many countries, packages must be child-resistant, tamper-evident, and easily readable, especially for over-the-counter products. That’s where pharma packaging printing becomes crucial—not only for aesthetics but for safety.

Why Design and Material Matter in Medicine Packaging

There’s an increasing focus on how packaging impacts both user experience and brand perception. Well-executed medicine carton design can influence how trustworthy and high-quality a pharmaceutical brand appears to the consumer.

Beyond appearance, functionality is vital. For example, elderly patients may struggle with small text or hard-to-open packs, so human-centered design is gaining traction. At the same time, as sustainability becomes a key issue, many brands are exploring recyclable medicine packaging materials or reducing plastic usage altogether.

In fact, many companies are transitioning from traditional plastics to biodegradable alternatives without compromising the strength and integrity of the packaging. Still, pharmaceutical plastic packaging remains a popular choice due to its durability, transparency, and cost-effectiveness, especially when integrated with advanced pharma packaging systems that automate filling, sealing, and labeling.

The Role of Technology in Pharma Packaging Systems

The future of medicine packaging is increasingly high-tech. Smart packaging, serialization, and track-and-trace capabilities are becoming the norm as global supply chains demand transparency and patient safety. Advanced pharma packaging systems now combine automation, data capture, and security features in a single streamlined process.

Even the design process has become more sophisticated. Modern medicine packaging design tools allow manufacturers to simulate how a box or blister will perform during shipping, storage, and everyday use. Coupled with high-resolution pharma packaging printing technology, brands can produce customized designs that meet regulatory needs and stand out on pharmacy shelves.

How Friction Feeders Support Pharmaceutical Packaging Efficiency

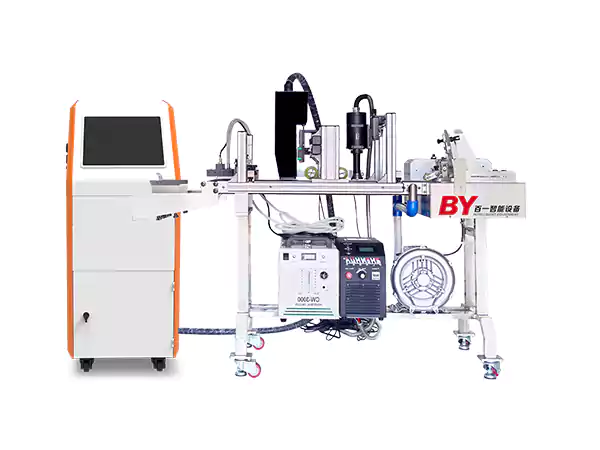

In high-speed pharmaceutical packaging environments, automation plays a critical role in maintaining accuracy, efficiency, and consistency. One key piece of equipment used in these operations is the friction feeder.

Friction feeders are widely used to feed flat items such as medicine packaging boxes, instruction leaflets, cartons, cards, and labels into packaging lines. These machines use friction to separate and feed products one at a time, ensuring a smooth, continuous process that reduces downtime and increases output.

In modern pharma packaging systems, friction feeders are integrated with labeling machines, inkjet printers, and cartoners. For example, during the pharmaceutical packaging process, a friction feeder can automatically feed unfolded pharmaceutical carton packaging into a printer for pharma packaging printing before it moves to the folding and filling stages. This automation not only boosts productivity but also improves accuracy in tasks like lot coding, date stamping, and leaflet insertion.

For pharmaceutical manufacturers dealing with small-batch production or high-volume SKUs, friction feeders offer a versatile and reliable solution. They support compliance by ensuring that every package receives the correct insert or label—an essential requirement under strict pharmaceutical packaging guidelines.

By combining advanced automation with thoughtful medicine carton design, friction feeders help bridge the gap between regulatory compliance and production efficiency.

My Thoughts

The landscape of pharmaceutical packaging is incredibly diverse, shaped by science, regulation, and design. From protective bottles and blister packs to sustainable pharmaceutical packaging boxes and advanced automation, every element contributes to ensuring that the medicine inside reaches the patient safely and effectively.

Whether you’re a pharmaceutical manufacturer, a packaging engineer, or a brand strategist, understanding the different types of pharmaceutical packaging and how they align with global pharmaceutical packaging guidelines is critical. As innovation continues, expect to see smarter, safer, and more sustainable packaging leading the way in healthcare.