Friction feeders in manufacturing are often underestimated machines that play an essential part in automating materials handling processes, increasing productivity, and providing accuracy. Although often out of sight and out of mind, friction feeds play an integral part in maintaining productivity and efficiency lines; they serve industries including printing, packaging, and direct mailing. This article gives more info. If interested!

What is a Friction Feeder?

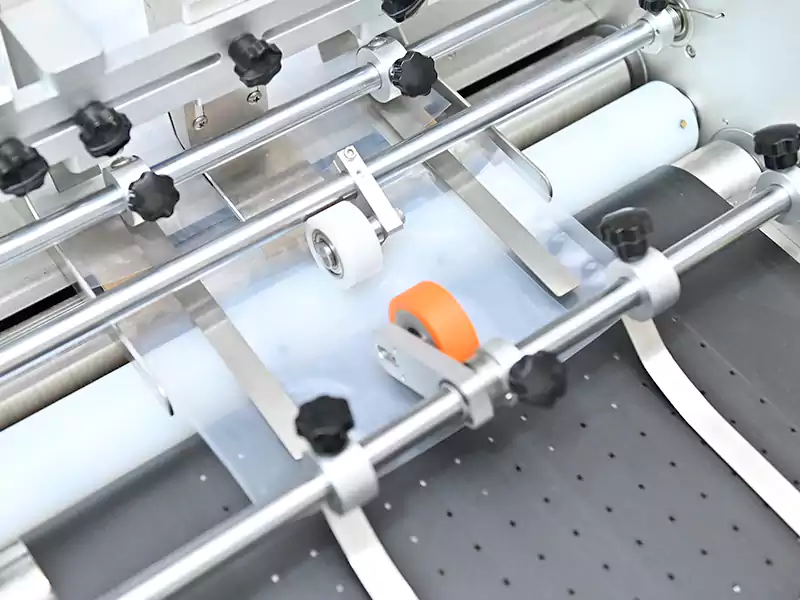

At its core, a friction feeder is a machine designed to move materials, typically flat items like paper, cards, or labels, using the force of friction. Instead of relying on traditional mechanical methods or conveyors, friction feeders use specially designed rollers that create enough friction to grab and move the material from one process to the next.

Friction feeders are commonly used in high-speed environments like printing presses and labeling lines, where precision and speed are vital. These machines ensure that materials are fed accurately and consistently without the need for manual intervention.

| Efficiency | 0-300 pieces/minute (Take 100mm size products as reference) |

| Body Material | Standard carbon steel baking paint |

| Belt Running Speed | 0-120m/min |

| Disposable Stacking | 100mm/200PCS (depending on the specific product size) |

| Applicable Materials | Various single-color pages, folding paper, cards, Instructions, labels, brochures |

| Support Integration | Labeling machines, printers, conveyors, and other products from major brands |

What is the Function of the Feeder Machine?

The main job of a feeder machine is to move materials from one stage of production to another. In simple terms, it’s like a conveyor belt, but more precise and reliable for specific applications. By automating the feeding process, friction feeders reduce the risk of human error, increase speed, and help streamline production lines.

Key Components of a Friction Feeder?

Understanding how a friction feeder works involves looking at its key components. Here’s a breakdown of the essential parts:

- Feeding Rollers: These are the parts that make it all happen. The rollers apply friction to the material, causing it to move along the machine and into the next process.

- Drive System: The motor or drive system controls the speed at which the material moves through the system.

- Sensors: These detect the presence of materials and send signals to ensure that everything is fed correctly and on time.

- Guide Rails: These keep the material aligned, ensuring it doesn’t veer off course as it moves through the system.

- Feed Hoppers: Feed hoppers help load materials into the system and ensure a continuous flow of items.

How does a friction feeder work?

A friction feeder works by gripping materials using rollers that rotate at high speed, creating friction. As the rollers rotate, they move the material forward. The system is designed to move materials consistently and with great precision, ensuring everything from paper sheets to labels is handled correctly. The integrated sensors monitor the material’s position, ensuring the next item is ready to be fed without interruption.

Why Should You Use a Friction Feeder?

Here are a few reasons why friction feeders are a go-to choice in many industries:

Friction feeders are a top choice across industries for their efficiency, precision, versatility, and waste reduction. By automating material handling, they boost production speeds and enable 24/7 operation with minimal downtime. Their high accuracy ensures proper alignment for tasks like paper handling, label application, and card feeding. Versatile enough to handle various materials—paper, cards, labels—they’re ideal for printing, packaging, and direct mail industries. Additionally, they minimize human error, reducing mistakes and material waste, which translates to long-term cost savings.

What are the uses of feeders?

Feeders are used in many different industries. They are especially popular in environments where materials need to be moved efficiently from one process to the next. Here are some typical uses:

- Friction Feeder for Paper Handling: In the printing industry, friction feeders move paper from stackers to printing presses with precise alignment.

- Friction Feeder for Label Application: These feeders ensure that labels are applied correctly to packages or other flat products.

- Friction Feeder for Card Feeding: Card feeders are used to move cards, such as business cards or credit cards, in processes like embossing, printing, or packaging.

Friction Feeder vs Vacuum Feeder

When comparing friction feeders vs vacuum feeders, the main difference lies in the method used to move materials. Friction feeders rely on rollers that use friction to grab and move materials, while vacuum feeders use suction to pull items through the system. Each has its pros and cons, but friction feeders are typically better for handling rigid materials like paper or plastic cards, while vacuum feeders are more suited for lightweight or flexible materials.

Maintaining Your Friction Feeder

To keep your friction feeder in top condition, regular maintenance is a must. Here are a few tips for maintaining your friction feeding system:

- Roller Maintenance: Over time, feeding rollers can wear down. Regular inspection and replacement will ensure your feeder works at full capacity.

- Clean Sensors and Guides: Dirt and debris can interfere with the sensors and guide rails. Cleaning them regularly ensures your feeder remains accurate.

- Lubrication: Keep all moving parts well-lubricated to reduce wear and tear and prevent friction-related issues.

- Check the Drive System: Ensure that the drive motor is functioning properly. A malfunctioning motor can lead to inconsistent feeding.

What is the purpose of a feeder system?

The purpose of a feeder system is simple: it’s there to handle materials automatically, from one process to the next. Whether it’s feeding paper into a printer or cards into a packaging machine, the feeder ensures a continuous and efficient flow of materials. This automation is essential in high-volume industries, where even a small delay can affect production timelines.

Applications of Friction Feeders

Friction feeders are used in many industries where high precision and speed are required. Here are some applications:

- Printing and Packaging: In the printing industry, friction feeders for paper handling are crucial for ensuring smooth and accurate paper feeding into printers.

- Direct Mail and Labeling: In the direct mail industry, friction feeders help apply labels or insert materials into envelopes with precision.

- Assembly Lines: Friction feeders are used to move parts and materials on assembly lines, ensuring a steady flow of items into each workstation.

- Other Industries: These machines can also be used in a variety of other sectors, including pharmaceuticals, food packaging, and electronics.

In summary, friction feeders are an indispensable part of modern manufacturing. They help automate material handling, reduce human error, and ensure materials are fed accurately into the production line. Whether you need a friction feeder for paper handling or for label application, these machines provide a versatile solution to streamline production processes. With proper maintenance and care, a friction feeder can serve your production line for many years, boosting efficiency and cutting down on waste.