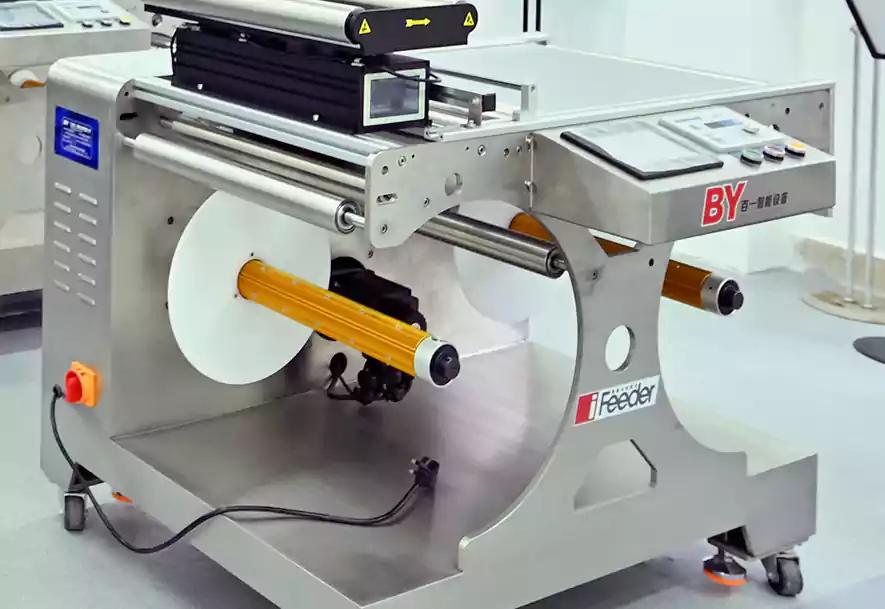

In the dynamic realms of label manufacturing and flexible packaging, rewinder machines are pivotal. A rewinder machine is a specialized device that takes large rolls of material, such as films or paper, and rewinds them into new, smaller rolls after various production processes, ensuring uniform tension and high-quality output. These systems handle BOPP film rewinding technology, a staple for high-gloss labels and moisture-resistant packaging. Modern rewinders integrate features like servo-driven tension control and integrated vision inspection systems, which scan for defects such as micro-scratches or print misalignments in real time. For example, a leading European label manufacturer reported a 30% increase in the conversion speed of its automated rewinders and a reduction in downtime through the utilization of integrated production lines and adjustments to automated deskew technology.

Flexible Packaging Rewinding Systems: Efficiency Meets Innovation

Roll-to-roll packaging equipment lies at the core of flexible production lines, enabling seamless transitions from lamination to slitting. Here, slitting in packaging is the process of cutting large rolls of material into narrower widths, ensuring that each roll meets precise size specifications required for labels or packaging. These systems are critical for materials like biodegradable PLA films, where biodegradable film compatibility with servo rewinders ensures gentle handling to avoid tearing.

Key advancements include:

- High-speed label rewinder solutions achieving 1,000+ labels/minute, synchronized with digital printers for variable data label rewinder synchronization (e.g., unique QR codes). In these systems, the purpose of rewinding is to collect the processed material into a consistent, high-quality roll that is ready for further conversion or direct use.

- Tamper-evident label rewinding processes, where precision slitting ensures perforations align perfectly with security seals, are critical for pharmaceutical packaging.

In label rewinding, the machine works by taking the printed label material and rotating it onto a new core. It uses advanced tension control and precise mechanics to ensure that labels are wound correctly, with minimal damage or misalignment. This process is essential in maintaining quality and efficiency throughout production.

Preventing Downtime and Static: Technical Mastery

1. How to Prevent Static Buildup in Film Rewinding:

- Ionized air knives neutralize charges, critical for static-prone materials like PET films.

- Humidity-controlled chambers reduce friction-induced static in compostable laminates.

2. Cost of Machine Downtime in Flexible Packaging Lines: Unplanned stops cost upwards of $500/minute in high-volume lines. Advanced rewinders mitigate this via predictive maintenance algorithms and rapid auto-splice systems, reducing downtime by up to 70%.

Process Integration: Lamination and Beyond

In the production of flexible packaging, lamination is a crucial step. Lamination in flexible packaging involves the bonding of multiple layers of films or materials to create a composite structure that improves barrier properties, durability, and visual appeal. This laminated structure then moves through roll-to-roll processing, where the precise slitting and rewinding ensure the final product meets strict quality standards.

Case Study: Speed and Sustainability in Action

A North American packaging firm adopted high-speed label rewinder solutions with IoT-enabled sensors, achieving:

- 30% faster changeover with automatic core loading and preset tension profiles.

- Zero material waste in biodegradable film production, thanks to servo-driven adjustments and real-time defect detection.

This example highlights how advanced label rewinders not only answer the critical question of how does a label rewinder work?—by ensuring the smooth, automated transition of printed materials into finished, ready-to-use rolls—but also how they integrate seamlessly into broader flexible packaging lines.

In short, from mastering BOPP film rewinding technology to enabling tamper-evident label precision, rewinder machines are indispensable in balancing speed, sustainability, and smart automation. Their operation—redefining processes from rewinding and slitting to lamination—ensures that every step is optimized for quality and efficiency. As industries prioritize eco-friendly materials and digital integration, these systems will remain central to cutting-edge packaging innovation, addressing the core purposes of rewinding: to produce uniformly high-quality, roll-ready material essential for further manufacturing and packaging applications.