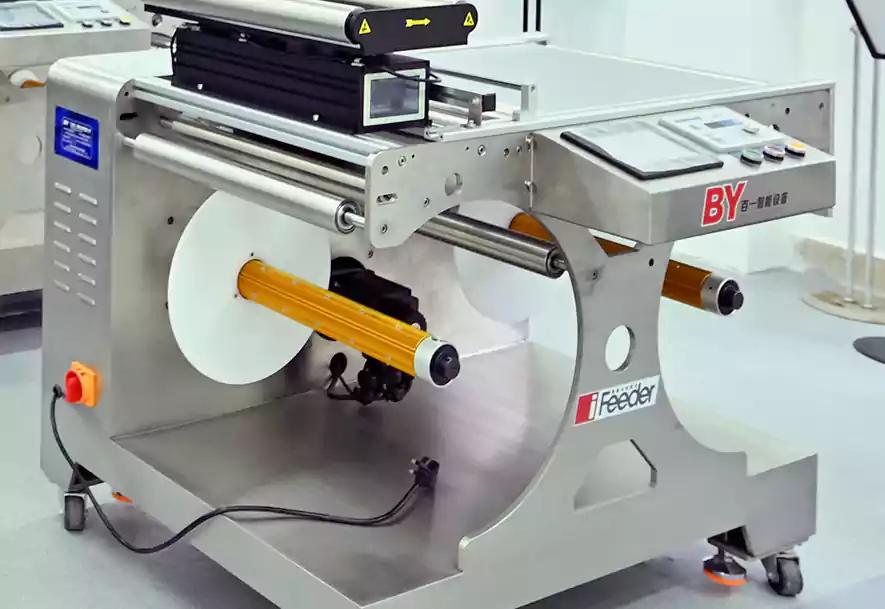

Automatic Rewinder Machine

Our rewinder machines enable efficient roll-to-roll processing across a wide range of materials including BOPP, CPP, PET, PE, paper, composite film, and more. With a focus on structural precision, ease of integration, and long-term growth value, our systems are built to elevate industrial production workflows.

- Intelligence Control System

- Seamless Integration with Inspection and Printing Systems

- OEM and ODM Services

Trustworthy Rewinding Machine Manufacturer

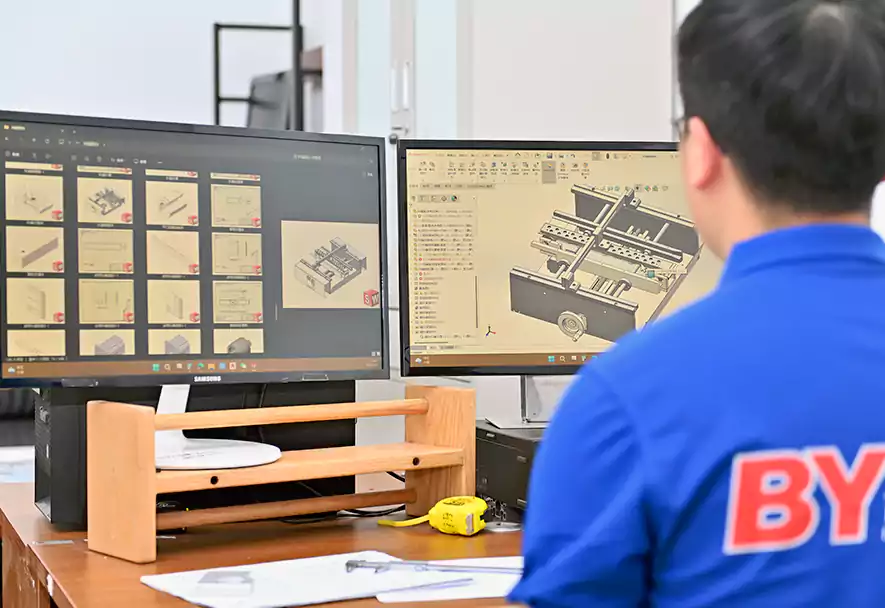

BY has more than 15 years of experience as a rewinder manufacturer and can customize roll to roll rewinding machine solutions according to customer needs, including label rewinders, paper rewinders, film rewinders, etc. Our machines can not only handle standard rewinding, but also support key functions such as fixed length rewinding, counting and more. Our advantages lie in the combination of high-precision servo drive system with PID speed regulation and a strong R&D team to meet your unique customization.

Our Rewinding Machine's Application in Reality

We are committed to testing product quality in real production environments and continuously improving our machines to solve customer challenges. Our video demonstrations include applications like automatic label rewinders for food packaging.

Automatic Label Rewinder Solutions

Re-roll Laser Printing

Ribbon Rewinder Solutions

Performance, Ease, and Integration

We design our machines for intuitive operation and seamless integration. Featuring touchscreen interfaces, sensor-guided roll tracking, and compatibility with CIJ/TIJ printers, lasers, UV dryers, and labeling systems, BY rewinders meet the modern needs of flexible packaging, pharmaceuticals, and household product production lines.

High Precision Rewinding Accuracy

Our rewinder machines are equipped with a deviation correction system that uses advanced sensors to monitor the position and deviation of the roll. This mechanism quickly adjusts any misalignment, maintaining a precision level of ±0.2mm. Such high accuracy is consistently applied across our product range, including the CE certified horizontal rewinder, which combines robust design with strict compliance with international safety standards.

Business Opportunity and Growth Potential

As your OEM/ODM partner, BY provides more than just a machine offers a path to long-term growth. Our after-sales services include rapid-response technical support, upgrade consulting, and tailored engineering solutions. Whether you’re scaling production, entering new markets, or optimizing packaging workflows, our team is here to grow with you.

Structured Engineering and Material Compatibility

Each machine is built with reinforced aluminum and 201 stainless steel for lasting performance and material adaptability. We ensure compatibility with a variety of film, paper, and composite materials. Optional CE certification provides additional safety assurance for international applications. The combination of sturdy construction and multi-material support ensures reliable long-term use.

Why Choose BY Rewinding Machine

BY has been exploring roll-to-roll application technologies for a variety of materials for many years, and is committed to finding the most optimal solutions for post-press processing in the printing, pharmaceutical, food and household product industries.

Our experienced support team ensures smooth setup, training, and long-term maintenance, so you can focus on production.

Backed by 100+ patents, our innovation is driven by user needs and evolving applications. Our R&D team collaborates with academic institutions to co-develop future-ready technologies.

Whether adjusting shaft sizes, roll widths, or signal output formats, our engineering team can tailor the machine to your exact workflow.

We Make It Easy to Work Together

No complex forms. No long wait times. Just clear, direct answers from real people who know rewinder machines inside and out.

You Tell Us What You Are Rewinding

Let us know the type of material—paper, film, label, or other. Each material has different tension and handling requirements.

You Share Roll Size and Speed Requirements

Tell us the max roll width, diameter, and preferred working speed. This helps us choose the right frame size, motor, and tension system.

You Describe Any Extra Functions Needed

Do you need slitting, counting, alignment, or tension control? Let us know your workflow and goals.

Our Engineers Recommend The Right Solution

Based on your inputs, we recommend the best-fit rewinder machine, with specifications, optional features, layout drawings, and quotation.

You Get Fast Support And Production Updates

Once confirmed, we start manufacturing and keep you updated. Our support team is ready before and after delivery.