Flat pouch packaging has taken center stage in the packaging world — and for good reason. Whether you’re a specialty coffee roaster searching for the perfect flat bottom coffee bag or a skincare startup needing custom printed pouches with eye-catching designs, flat pouch formats offer a flexible, sleek, and cost-effective solution.

So, what is a flat package exactly? Think of it as a compact, often heat-sealed pouch made from laminated film. It’s lightweight, lays flat when empty, and can be tailored with various sealing and structural options. Brands across industries, from pet food to pharmaceuticals, are turning to flat pouch packaging to elevate both product preservation and brand perception.

One of the most significant advantages of pouch packaging lies in its efficiency. Compared to rigid containers, flat pouches take up less space during transport and on shelves. They require fewer raw materials and are compatible with eco-conscious substrates, making them a smart option for sustainability-driven companies. Their wide, printable surfaces are ideal for flat pouch printing, allowing vibrant designs and detailed product information to shine.

When it comes to materials, flat pouch packaging typically involves multi-layer laminated films such as PET/PE, PET/AL/PE, or kraft paper laminates. These structures are selected based on the product’s sensitivity to oxygen, light, or moisture. For example, a flat bottom bag packaging used for roasted coffee often includes a metalized layer or valve to protect freshness and aroma.

The beauty of pouches is in the details, especially the sealing. There’s more than one way to close a pouch: three-side seals for simplicity, zippers for reusability, and even gussets for added volume and strength. The flat bottom stand up pouch is a prime example with its reinforced base and upright posture. It combines stability with visual appeal, making it especially popular in the specialty food market.

What’s even more compelling is the versatility of formats available. Beyond basic pillow pouches, there are resealable zipper bags, flat bottom coffee bags, retort pouches for ready meals, and spouted versions for liquids. Brands often opt for custom flat pouch packaging to match their exact specifications, whether it’s for bulk tea, granola, cosmetics, or nutritional powders.

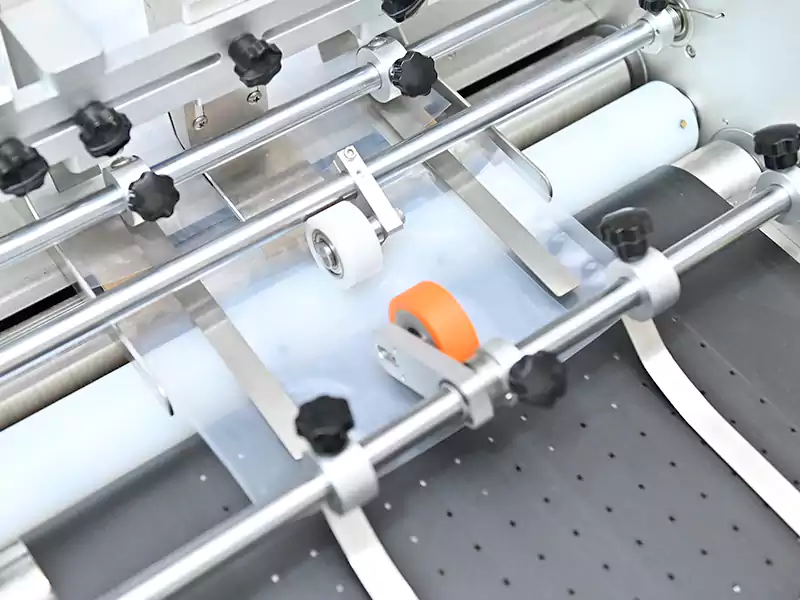

Of course, beautiful packaging must also be practical. That’s where automation and technology come into play. Modern flat pouch packaging machines are designed to handle forming, filling, and sealing at high speeds. And when integrated with alimentatori a frizione, they gain the ability to feed pouches, inserts, or cards smoothly and consistently — an essential step for automated labeling or coding. This type of friction feeder integration helps maintain efficiency and accuracy in high-volume production environments.

In the end, flat pouches are more than a packaging trend — they’re a strategic choice. Their adaptable structure, compatibility with high-resolution flat pouch printing, and support for custom flat pouch packaging make them a go-to solution for companies aiming to stand out while staying lean.

If your business is seeking flexible packaging that delivers on form and function, it’s time to look closely at the flat pouch, because sometimes, thinking flat is the best way to stand out.