Related Recommended Products

- Friction Feeders44 products

- Paging Machines2020 products

- Rewinder Machines66 products

- Vacuum Feeders33 products

Imagine your production line humming along without a single hiccup—no stop‑start grinding, no frantic manual reloading. That’s the promise of a stream feeder. At its heart, a stream feeder is a continuous‑motion system that takes a pile of loose items—sachets, cards, pouches—and lines them up in a smooth, never‑ending flow into your printers, labelers, or assembly machines.

What is a Stream Feeder?

In simple terms, a stream feeder is an on‑demand feeding machine that combines gentle vibration and precise guides to take loose, flat, or irregular items, like sachets, cards, pouches, or leaflets, from a bulk hopper and deliver them one after another in a constant, controlled flow. This means your downstream printers, labelers, sealers, or assembly stations never run out of parts.

Application of Stream Feeder

You’ll find stream feeders putting their steady magic to work across a wide range of industries, each with its own unique demands:

Pharmaceutical & Healthcare

Stream feeders keep critical components like blister cards, patient instruction leaflets, and sample sachets flowing into packaging and labeling stations without interruption. This reliability helps maintain compliance with strict dosage labeling and traceability requirements.

Food & Beverage

Whether you’re packaging sauce packets, spice sachets, or single‑serve condiment pouches, stream feeders deliver hygienic, high‑speed handling that meets food‑grade standards and minimizes product waste.

Cosmetics & Personal Care

From trial‑size sample sachets to box inserts and foil sachets, stream feeders handle delicate, lightweight items with zero jams, keeping your production line smooth and adaptable to rapid product line changes.

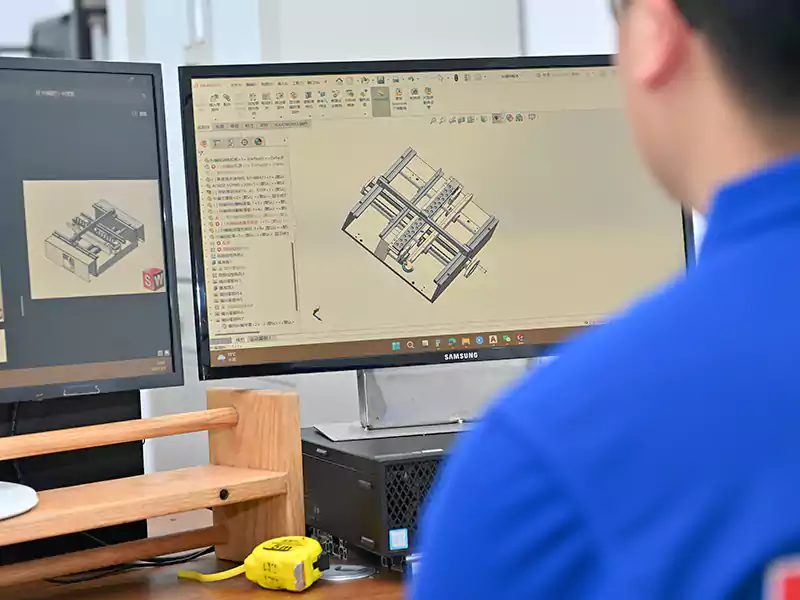

Electronics & Industrial

In electronics assembly, stream feeders line up ID cards, labels, component trays, and foam inserts for precision printing or mounting. For industrial parts like gaskets or small brackets, continuous feed prevents bottlenecks in busy assembly cells.

Automotive & Packaging

Stream feeders supply mounting brackets, decorative panels, and parts tags directly to sealing and labeling machines on auto‑assembly and packaging lines, synchronizing seamlessly with robotic cells and conveyors.

Publishing & Print Finishing

Ideal for high‑volume mailers, promotional inserts, and book block feeding, stream feeders integrate with ink‑jet and laser printers to automate variable data printing and finishing tasks.

Seed & Agricultural Packaging

For precision dispensing of seed packets, fertilizer sachets, or small agricultural samples, stream feeders ensure each pouch is correctly oriented and positioned at high throughput.

Unlike intermittent systems, a stream feeder keeps everything moving at a consistent clip. Parts settle into a vibratory hopper, get gently aligned on singulation tracks, and glide forward on a conveyor or vacuum rail. The result? Throughput rates that can soar past 1,000 parts per minute and far fewer jams.

which pause between parts, a stream feeder keeps everything moving at a consistent clip. Parts settle into a vibratory hopper, get gently aligned on singulation tracks, and glide forward on a conveyor or vacuum rail. The result? Throughput rates that can soar past 1,000 parts per minute and far fewer jams.

But why should you care? First, think about your bottom line. Faster line speeds mean more output and lower labor costs. Many of our customers see a 125% boost in parts‑per‑minute and slash downtime by 80%. Even better, changeovers take under five minutes—just swap out the quick‑release rails, tweak the track width, and you’re back in business.

Of course, precision matters too. If you’re feeding delicate or tiny parts, a vacuum feeder’s pick‑and‑place approach might seem tempting. It offers sub‑millimeter placement accuracy, but at the cost of a slower, stop‑and‑go rhythm and extra setup for nozzles and vacuum lines. When your parts are flat or flexible—think printed leaflets, sachets, or ID cards—you’ll appreciate the steady, reliable spacing a stream feeder provides.

Keeping your stream feeder in top shape is straightforward. A quick daily glance at sensors and guards, weekly belt‑tension checks, and a monthly vibration motor tune‑up will keep jams at bay. And if something does come up—whether it’s a pesky jam at the hopper entry or a misaligned track—simple adjustments get you back on track fast.

Compliance and security are also essential. Our equipment complies with CE and UL standards and conforms to the ISO 9001 system. We can customize solutions according to your standards.

Ready to see a stream feeder in action? Let’s talk about your parts and your goals. We’ll run a live demo—either at our lab or on your line—so you can compare specs, crunch your ROI numbers, and decide if this continuous feed is the right fit. Reach out today, and let’s keep your production moving without missing a beat.