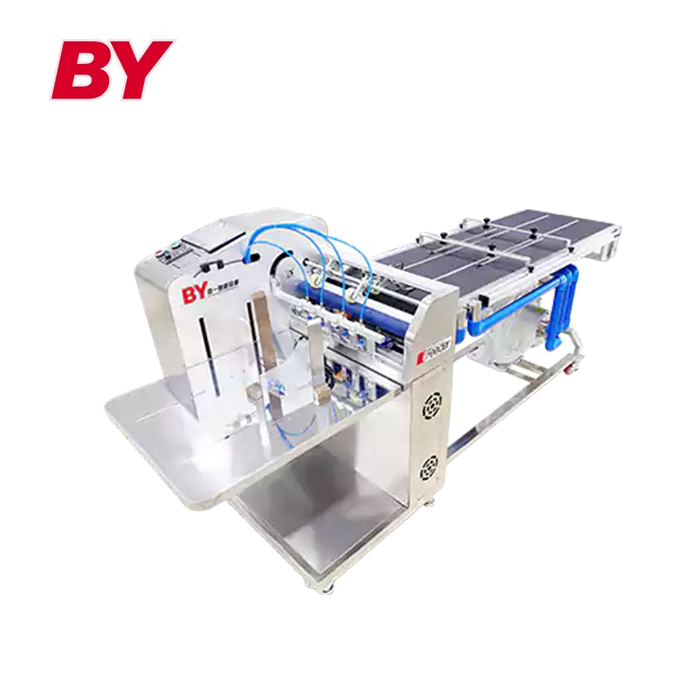

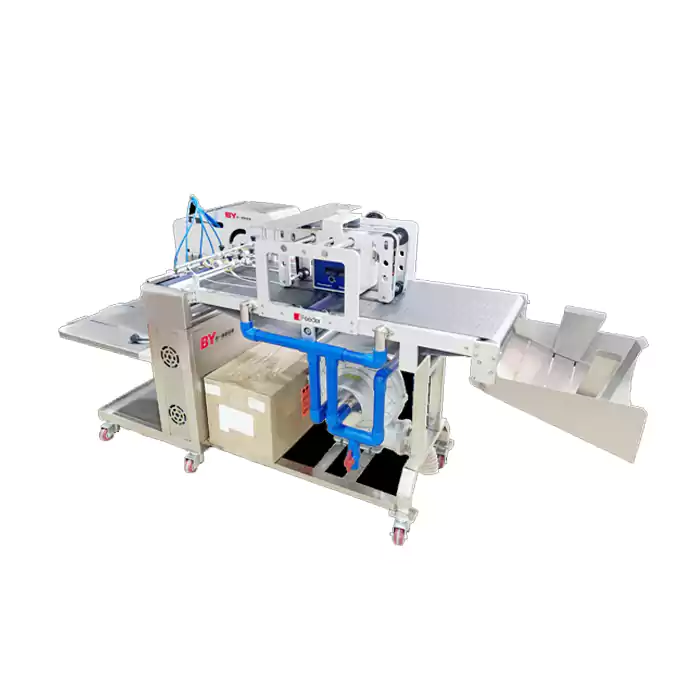

Friction Feeder Machines

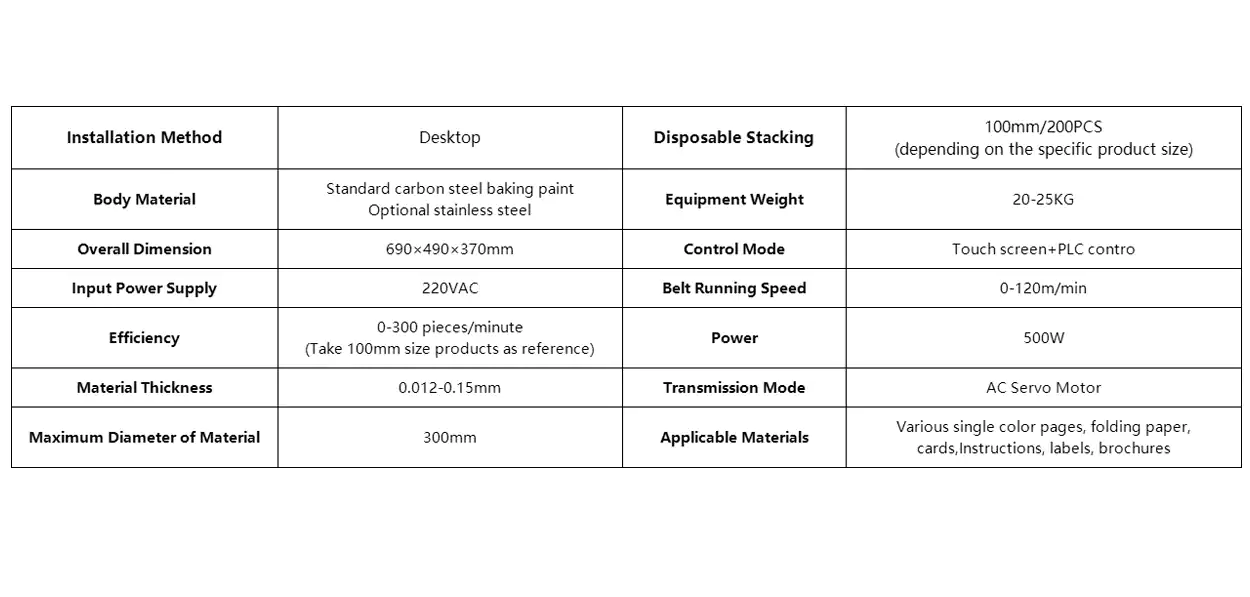

Our high-performance friction feeding machines are designed to automatically feed flat products such as paper, cartons, pouches, cards, and leaflets into your packaging line. Our solutions ensure high speed (up to 120 m/min) and precision. It is typically available as a stand-alone friction feeder unit or integrated with a conveyor system.

- Customize and Match with Your Materials

- 500 to 1000W High-performance AC Servo Motor

- Over 15 Years of Mature Technology

Professional Friction Feeder Manufacturer

We are your trusted friction feeder manufacturer, offering a full range of models from friction feeders to suction-type feeders, including card feeders, paper feeders, booklet feeders, and more. Our systems replace manual feeding of paper, labels, cartons, and more, seamlessly integrating with your existing lines to boost throughput, reduce labor costs, and enhance overall efficiency.

Leveraging our professional friction feeder design capabilities and deep industry knowledge, we deliver fully customized solutions tailored to your product mix and production goals.

Record Our Successful Cases

Over the past decade, we have always believed that good quality is the key to retaining customer loyalty.

Precision feeding of cards into automated pick-and-place systems.

Listen to Your Needs and Work Hard to Achieve Them

Why Choose Our Friction Feeder Machines

Our product technology is independently controlled and we hold multiple patents. We have the technical capabilities to help you solve your flat packaging feeding problems.

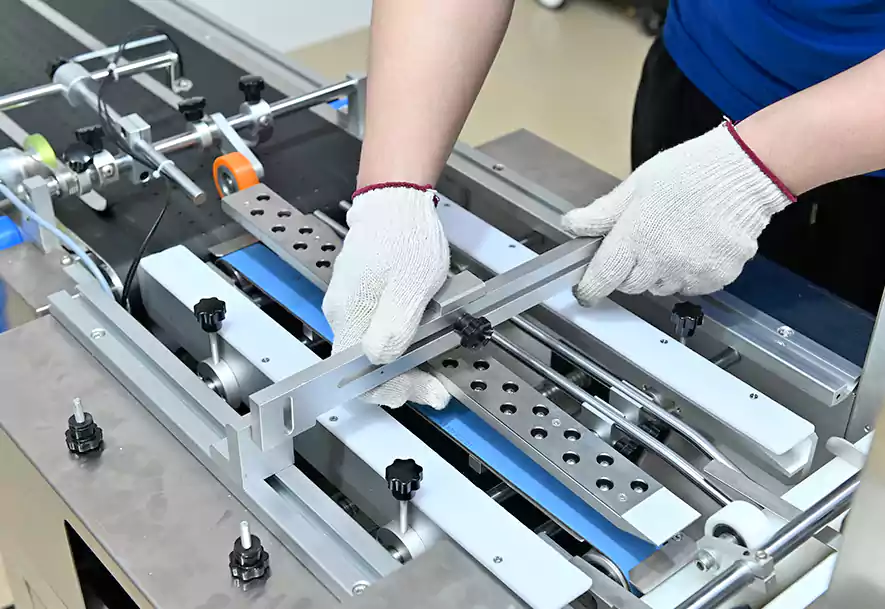

Our bodies are made from aluminum and 201 stainless steel raw materials. We also test its physical properties to ensure that it meets production standards.

The feeding speed and inlet can be adjusted easily to synchronize effectively with your production line, whether integrated into a high-speed conveyor system or operating within a more compact setup.

Our founders are technologists and have been specialising in technology and keeping an eye on future trends to better serve your business.

Based on your production requirements, we offer fully customized services, including tailored functions, adsorption belts. This customization extends to systems like the CE certified automatic feeding system that meets operational standards.

Our product warranty is 1 year, and easy to purchase replacement wearing parts in the local market, and long-term online support technical guidance services.

Our equipment are easy to install and is controlled by a touch screen and PLC, making it quick to get started after simple operator training.

Advanced Friction Feeder Automation Solutions

At BY, we understand the importance of seamless integration. Our friction feeder automation system is designed to synchronize perfectly with your existing packaging lines.

Whether you need to dispense cards, bags, or instruction manuals, our friction feeder machines are equipped with advanced PLC control and sensor arrays. This allows for precise batch counting and "on-demand" feeding triggered by external signals, ensuring zero errors in the automated process.

We offer flexible solutions, ranging from standalone tabletop friction feeders for semi-automatic manual workstations to high-performance units that can be directly integrated into automated production lines.

Versatile & Practical Functions

Our friction feeder conveyor can provide reliable performance in various applications. Their modular design and intelligent features make them practical and flexible, including vision feeding and alignment, batch raceability, and other functions.

Our high-resolution camera detects feed jams and misalignment instantly, starting automatic corrections. Any flat items that are not within specifications will be diverted to safety.

Every unit is timestamped and recorded, and complete batch histories are archived to facilitate audit and recall processes.

CE-certified hardware that includes sensors can stream performance metrics directly to your dashboard. This allows you to monitor line status and trigger alerts. You can also access historical data at any time.

Compatible with a Wide Range of Materials

Automatic high speed friction feeder machines can be applied to many types of materials, such as gift cards, credit cards, loyalty cards, envelopes, pamphlets, booklets, advertising pieces, and pouches. Could you communicate with our engineers to test your sample?

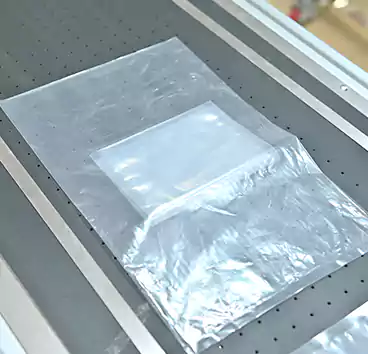

Sealed Packagings

Cassettes

Wide Flexible Film Packagings

Food Packagings

Plastic Packagings

Applications of Friction Feeders

Our friction feeders have applications across a variety of industries due to their adaptability, gentle handling and ability to manage a wide range of materials.

Feed flat items such as envelopes, paper, food packaging, cards, etc. into a printing or packaging machine.

Feed letters, labels, tags, coupons or small packages of goods (such as cosmetic samples) into the automated sorting line.

Feed food bags, medicine boxes, clothing tags, and wine packaging into the labeling machine to complete QR codes, bar codes, and ingredient lists.

The Ultimate FAQ Guide of Friction Feeders

Complete FAQ Guide

Can your friction feeder handle variable product sizes?

Yes, our friction feeders feature tool-less adjustment. Operators can easily adjust the width guide rails and discharge gates to switch between different product sizes in less than 10 minutes, making it ideal for multi-SKU production lines.

Do you support feeding odd-shaped or non-rectangular products?

Standard friction feeders work best with rectangular items. However, for irregular shapes, we offer customized assist belts and special discharge extensions to ensure stable separation and feeding.

How do you handle shipping and installation support?

We ship worldwide via sea. Our machines are shipped 90% pre-assembled. We provide detailed video tutorials and remote video support to guide your team through the installation and commissioning process (usually completed in under 1 hour).

How do you prevent "double feeding" (two products at once)?

BY friction feeders utilize double sheet detection to actively prevent multi-feeds. This assures strict single-sheet processing.

What is a Friction Feeder and How Does it Work?

A friction feeder is an automatic feeding device used in packaging and printing lines to separate and feed flat products, such as paper, cartons, labels, or pouches, one by one. It works by using friction belts or rollers to grip the bottom item from a stack and feed it forward smoothly, ensuring accurate and continuous material delivery to downstream equipment like printers, labelers, or coding machines.