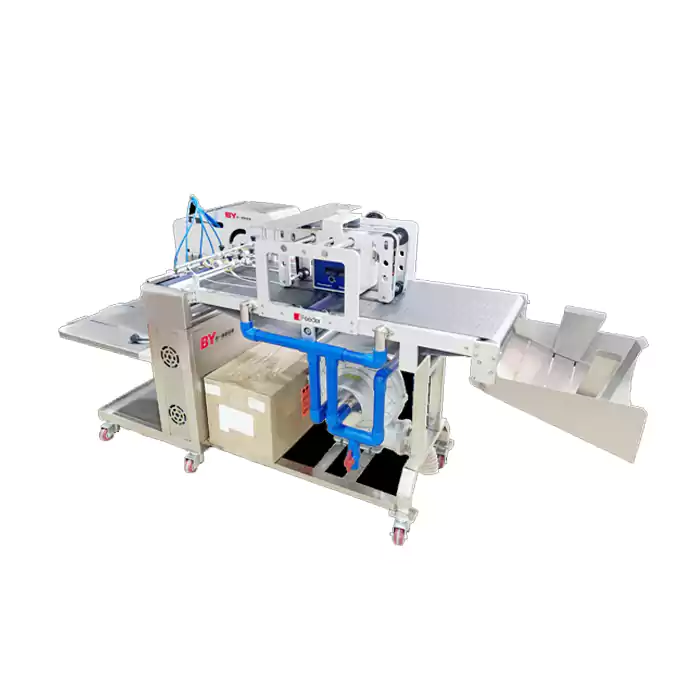

Feeding Machine

We specialize in feeding machines for flat packaging materials such as paper sheets, pouches, labels, cards, and cartons. With both friction feeding and vacuum feeding technologies, our machines deliver stable, precise, and high-speed feeding, ensuring smooth integration into printing, labeling, and packaging production lines.

- One-Stop Feeding Solutions

- Customizable Designs for All Industries

- Patented Intelligent Technology

Trusted Feeding Machine Manufacturer

As a professional manufacturer, we provide industrial feeding machines tailored for packaging, printing, and more. Our portfolio includes friction feeders, pouch feeders, carton feeders, and label feeders, designed to work with CIJ/TIJ inkjet printers, laser coders, and automatic labeling systems. With double-sheet detection, auto deviation correction, and rejection systems, our feeding solutions ensure error-free and continuous production.

Core Features That Improve Accuracy & Efficiency

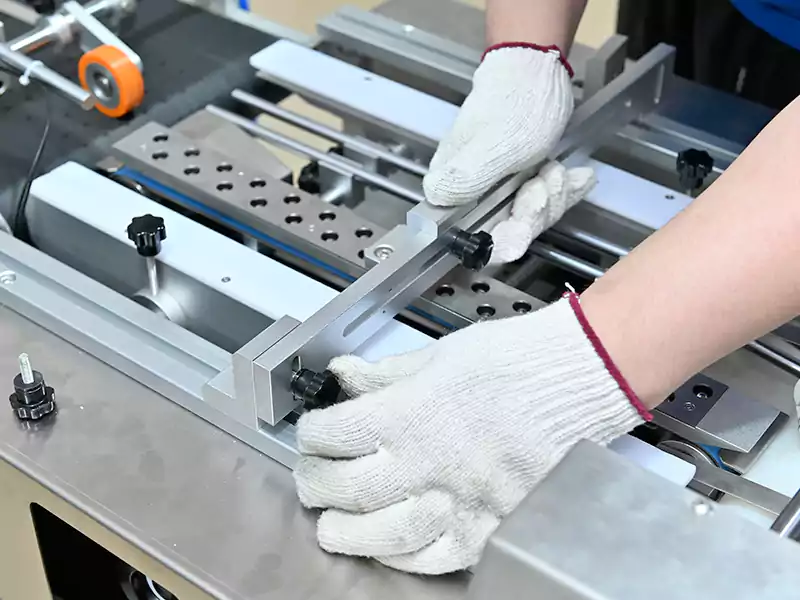

Our automatic feeder machines come with advanced technologies that improve production efficiency and precision.

Automatic Deviation Correction

We ensure sheets, pouches, or labels are always aligned during feeding, even at high speeds.

Seamless Production Line Integration

We easily connect our feeding machines with printers, coders, laminators, UV dryers, and sealing machines, supporting variable data printing, inline labeling, and surface treatment.

Smart Control System

We offer PLC or in-house controllers with touchscreen operation, speed adjustment, alarm systems, and external signal control for flexible operation.

Feeding Machine Types for Different Needs

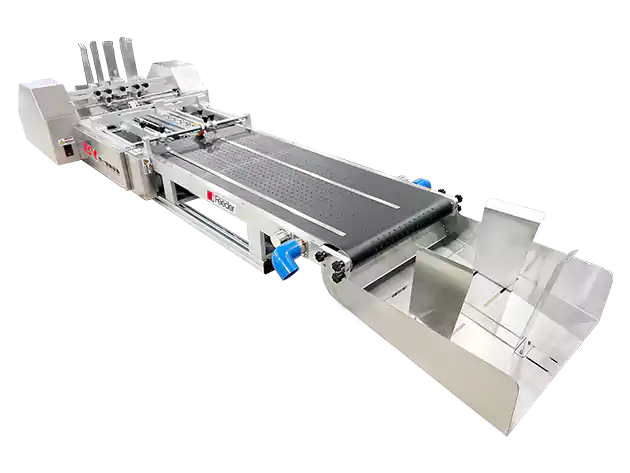

We provide different types of feeding machines to match your specific packaging materials and production requirements. Each model is engineered for accuracy, stability, and seamless integration into automated lines.

- Conveyor Type Feeding Machine

- Direct Feeding Machine

- Vacuum Feeding Machine

- Friction Feeding Machine

Quality, Durability, and Energy Efficiency

Our feeding machines are built with premium aluminum alloy and stainless steel, ensuring long-lasting durability, precision, and low-maintenance performance.

- Precision Manufacturing

- Strict Quality Control

- Flexible Design

- Low Maintenance

Global Service Support

We provide comprehensive after-sales service to ensure stable operation and long-term cooperation, including technical guidance, spare parts supply, intelligent alarm systems, and custom R&D support.

- 24/7 Expert Support

- Fast Spare Parts Delivery

- Smart Alarm System

- Tailored Solutions

Learn About Our Products Through Videos

We offer feeding solutions for a wide range of flat materials.

Different Business Development Needs Optional

Our feeding machines can be customized to meet diverse business growth and production requirements, providing flexible solutions for different industries and line setups.

Coding Function

Our feeding machines can be integrated with CIJ, TIJ, and more coding systems, enabling high-speed printing of batch codes, dates, barcodes, QR codes, and custom text or graphics. This ensures traceability, compliance, and accurate marking across your production line.

Labeling Function

We support inline automatic labeling for sheets, pouches, and more, streamlining packaging, reducing manual handling, and ensuring consistent labeling quality.

Inspection & Counting

We ensure accuracy and quality with integrated visual inspection and counting systems.

Other

This section covers additional optional modules and future upgrades, such as automatic tail collection, inline sealing, custom sensors, or any specialized attachments. It provides flexibility for unique production requirements and ensures your feeding machine can adapt to evolving business needs.

THE ULTIMATE FAQ GUIDE OF

Feeding Machine

Table of Contents

What is a feeding machine?

A feeding machine is an automated device designed to accurately and continuously feed flat materials such as paper sheets, pouches, labels, cards, and cartons into production lines. It ensures precise placement, stable operation, and seamless integration with printing, labeling, coding, or packaging systems, improving efficiency and reducing manual labor.

What is the difference between friction and vacuum feeding?

Friction feeders are versatile for most sheets and cards, while vacuum feeders use negative pressure to handle thin, slippery, or delicate materials.

Is it easy to maintain a feeding machine?

We provide installation guidance, operation training, and long-term technical support. Wear parts from third-party equipment are easy to source locally, and we also offer direct shipment of parts from our factory.