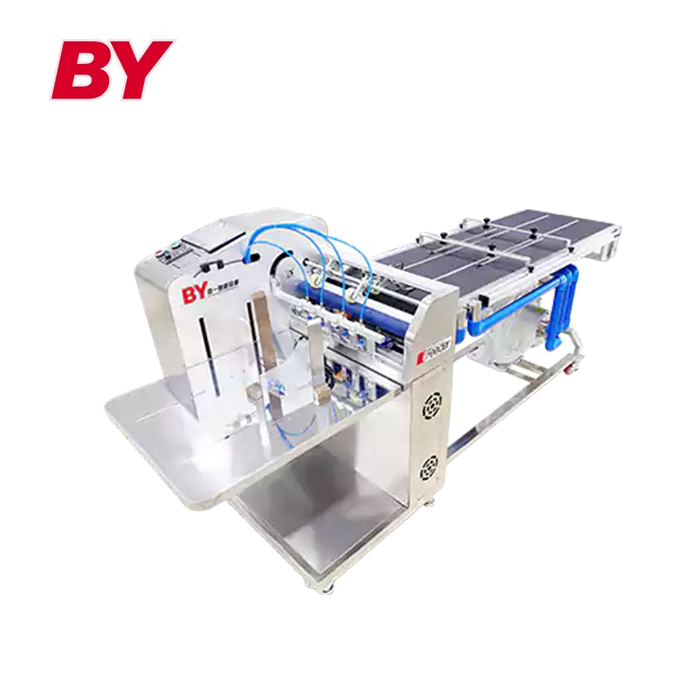

Customization

Customized solutions for flat packaging feeders for your specific application

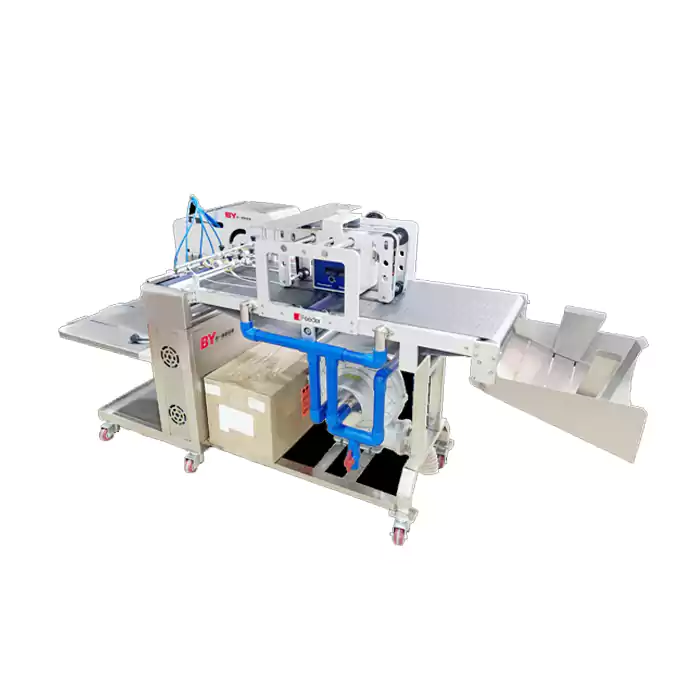

Module Expansion

Our Module Expansion business is based on proven industry knowledge support and enhances equipment performance and adaptability by adding, replacing, or upgrading different functional modules. This includes control systems, customized interfaces, and third-party production equipment, etc.

Inkjet printers

Labeling machines

Sealing machines

Laminating machines

Plasma processor

Automatic deviation

correction

correction

Sealing cullings

High temperature

drying

drying

Conveyor belts

Automatically calculate

quantity

quantity

Visual inspection

Negative pressure

adsorption

adsorption