Polariser, tempered film, mobile phone film, computer film, display film, etc.

The demand for electronic products is growing, and the demand for product accessories is also growing, such as: mobile phone screen film, for the production of polariser, the most taboo products are ‘scratched, contaminated’ and so on;

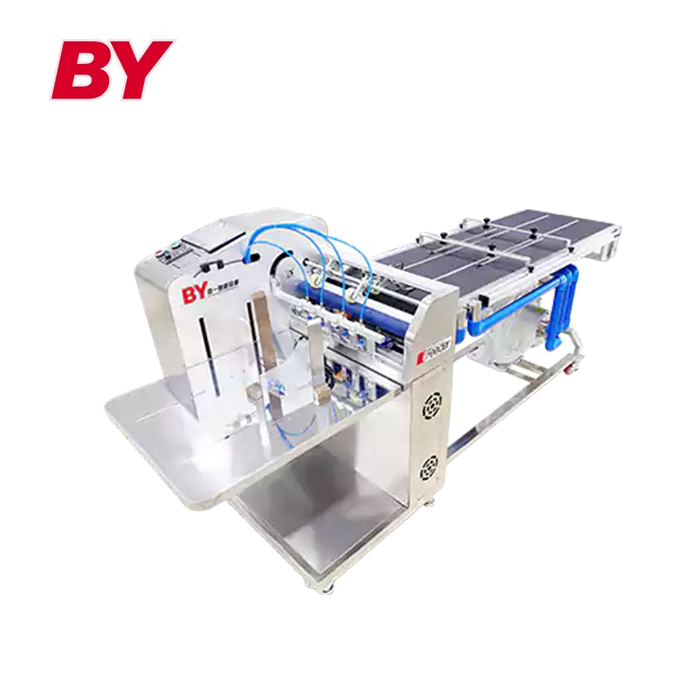

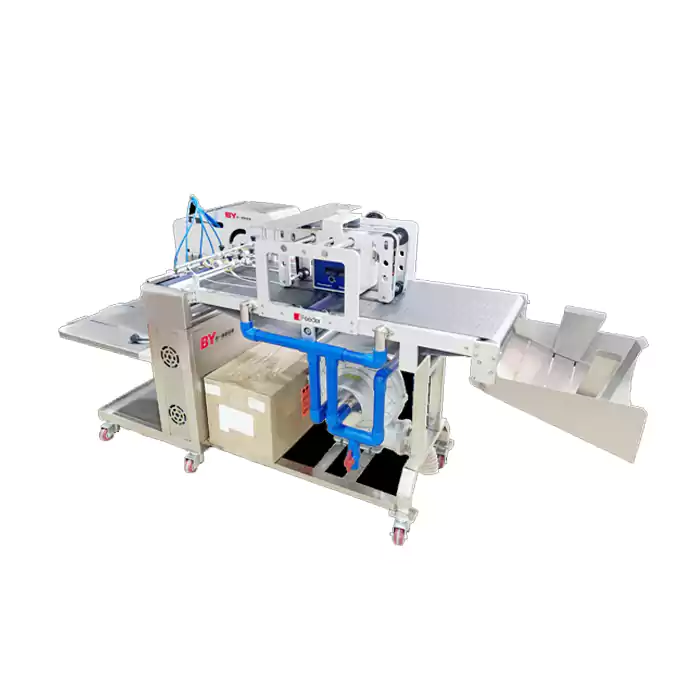

We received the views of manufacturers to actively develop and successfully manufacture: vacuum suction cup inkjet print feeder.

What are its components?

1, suction cup feeder: as the main operating platform, with 300mm high automatic lifting storage silo, which is different from the belt friction feeding, it is mainly sucked up the product with the suction cup way a sheet transferred to the conveyor belt.

It is important to note here: although it avoids the scratches caused by the friction feeder, but it is not as fast as the friction feeder in terms of speed and efficiency, and at the same time, suction cups need to stop to discharge the material, while the friction type can be done without stopping to continue to discharge the material.

After a series of inkjet printing on the conveyor belt, the product can smoothly enter the storage mechanism.

2、Inkjet printer: main console + printhead composition

What are the effects of this set of feeder to the production plant?

1, for special products worry about scratching, worry about dust pollution, this machine can be completely solved.