PCV card, exchange card, shopping card, points card, gift card, supermarket card, etc.

In recent years, with the amount of card exchange gifts, commodities more and more cases, the number of cards for the printing of a substantial increase; in this regard, we visited nearly 1,000 card manufacturers around the world, found that nearly 90% of the factories are manually discharged through the manual printing or labelling of cards.

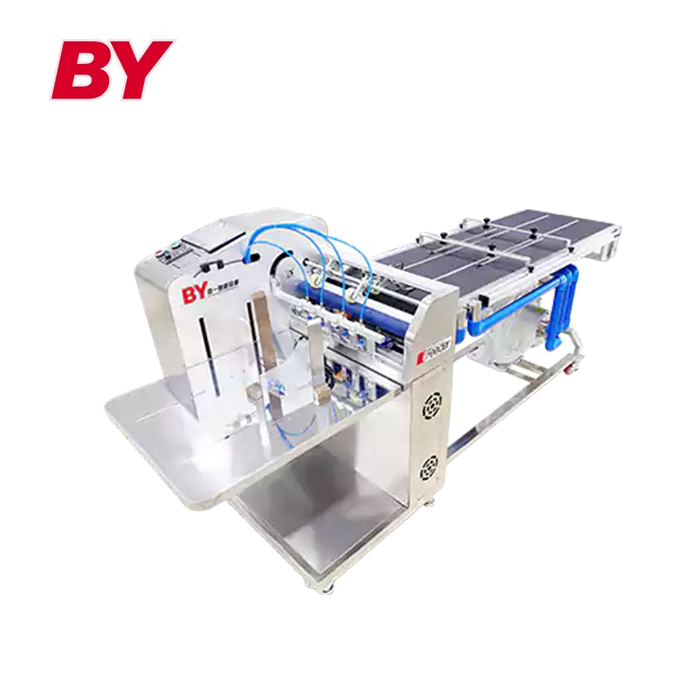

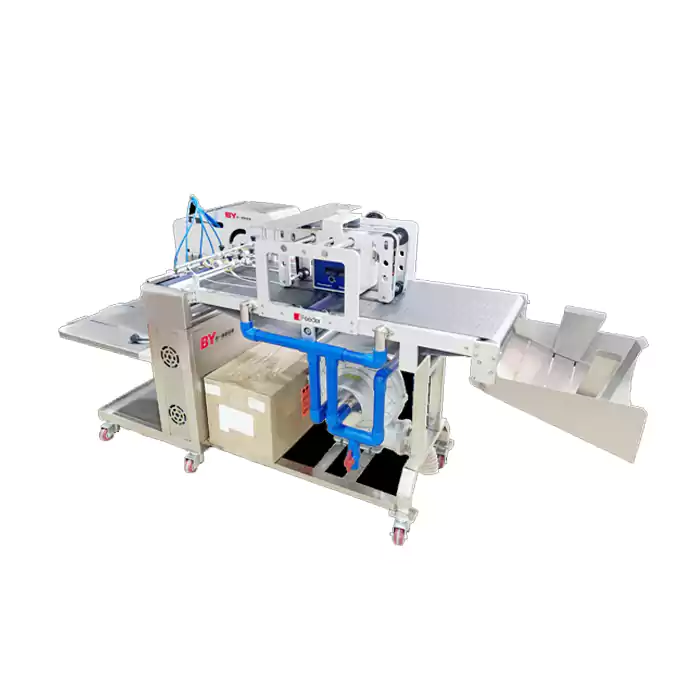

We have collected the views of the factory at the same time the successful development of this: high-speed friction inkjet printing photo inspection labelling integrated system!

What are its components?

1, high-speed friction feeder: as the main operating platform, with a 260mm high storage bin, workers only need to continuously to the storage bin stacked material, the product through the friction of the way a sheet transferred to the automatic correction mechanism for position correction, and then transferred to the conveyor belt.

In the conveyor belt for a series of inkjet printer photo detection, if the product appears to print unqualified or not be printed, then the system will not give this product issued the next step of the labelling action, the product will go directly to the automatic out of the agency as has been eliminated products;

If the product print test qualified, then the system will be issued to the product labelling action, after labelling smoothly into the qualified products in the storage institutions.

2, UV inkjet printer: mainly by the plasma processor (dealing with the surface of the stronger ink adhesion) + UV inkjet print head and control cabinet + ultraviolet curing lamp (dry) composition

3, visual inspection system: mainly by the camera + monitor + keyboard + mouse + real-time photo inspection system components

4、Automatic labelling system: complete labelling mechanism and system

This set of system to the card production plant to bring the impact of what?

The automatic feeding machine speed is far higher than the manual manual discharge speed, the output and efficiency get greatly improved.

The visual inspection system replaces the manual one by one to check whether the printing content is wrong, omits to print, does not print.