In today’s fast-paced manufacturing world, efficiency and precision are paramount. With the ever-increasing demand for quicker turnaround times and high-quality products, businesses are seeking innovative solutions to stay competitive. The adoption of automatic flat packaging feed systems is pivotal, these systems streamline operations by automating the feeding of stacked flat materials (e.g., cardboard, film, metal foils), eliminating manual intervention, and boosting productivity to meet consumer demands effectively.

Automatic feed systems for flat packaging are mechanized systems designed to transport and manage stacked flat materials (e.g., cardboard sheets, blister packs, plastic films) through packaging stages. These systems handle tasks like precisely separating and feeding individual sheets from stacked batches, ensuring seamless production flow without human error.

Types of Automatic Feed Systems

Today, we will mainly list two types.

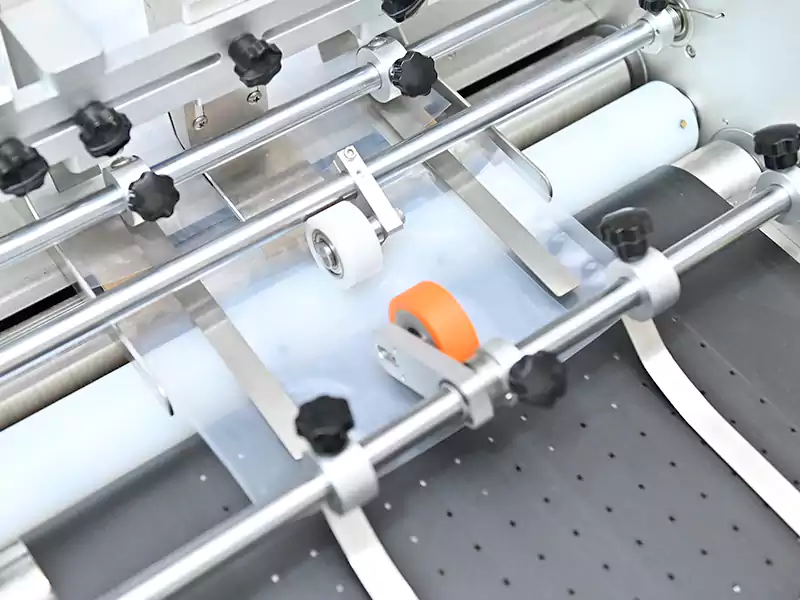

1. Batch Feeder: Through vacuum suction or friction, the system precisely separates and transports individual sheets/rolls of stacked flat packaging materials (e.g., cardboard sheets, film rolls, aluminum foils) to the production line.

2. Automatic Print and Apply Systems: These systems automatically print and apply labels to products, ensuring consistent and accurate labeling. This capability not only enhances the aesthetic appeal of the product but also ensures compliance with industry regulations concerning product information display.

Benefits of Using Automatic Feed Systems

Implementing automatic feed systems in your packaging operations comes with numerous advantages:

Increased Efficiency: By automating the feed process, companies can reduce manual labor and speed up the production line, resulting in agile operations that can adapt quickly to changing production demands without sacrificing quality.

Consistency: Machines operate with precision, ensuring uniformity in product handling and packaging, which builds customer trust and brand reliability.

Cost Savings: Minimizing errors through automation leads to significant long-term cost savings, as the initial investment is offset by reduced labor costs and waste.

Scalability: As your business grows, automatic systems can be easily scaled up to meet increased production demands without significant additional investment in labor or infrastructure.

Applications in Different Industries

Automatic feed systems find applications across various industries due to their adaptability and efficiency. Here are notable examples:

Food and Beverage Industry: Maintaining hygiene is critical. Automatic flat packaging feed systems transport packaging materials (e.g., folding cartons, tray blanks), reducing contamination risk and ensuring quality compliance.

Pharmaceutical Industry: Precision is vital. Automatic flat packaging feed systems ensure accurate feeding of medicine packs and foil sheets while maintaining regulatory compliance.

E-commerce and Retail: With the rise of e-commerce, the demand for efficient packaging solutions has increased. Automatic systems that apply shipping labels to bubble mailers are essential in speeding up the fulfillment process, enabling rapid processing and shipping of orders.

How to Implement Automatic Feed Systems

Implementing an automatic feed system requires careful planning. Here are key steps:

Assess Your Needs: Evaluate your current packaging process and identify bottlenecks. Determine how automation can improve efficiency and reduce costs.

Choose the Right System: Select a system that aligns with your production needs, considering factors such as product type, required speed, and precision.

Integrate with Existing Systems: Ensure that the new system can integrate seamlessly with your existing machinery and software for minimal disruptions.

Train Your Staff: Provide ongoing training and support to help your team adapt to and effectively manage the new automated systems.

Automatic feed systems are revolutionizing the packaging industry by enhancing efficiency, reducing costs, and ensuring consistency. By embracing these technologies, businesses can gain a competitive edge and adapt to the demands of modern consumers while supporting strategic objectives like sustainability and customer satisfaction.